At Dewatech, we treat and recycle contaminated waters, oils and sludge. We have a permit that allows us to treat up to 50 000 ton of waste each year. We treat the waste in a process that has been thoroughly crafted to ensure that the result is an ultra clean water that meets all the approvals required to be released at our recipient. Our recipient is Inrefjärden. We strive each day to make sure that we are ahead in our industry and that our plant is modern, up to date and well adjusted to meet the environmental requirements.

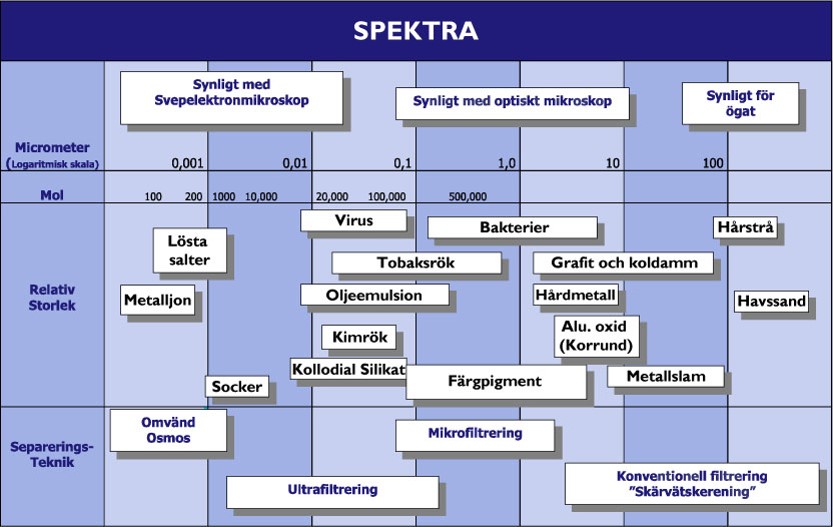

SPECTRA

Each batch of waste that arrives at our plant for purification contains of different components and has to be purified based on each individual composition. The spectra below explains different compositions and different methods we use to separate them from the water.

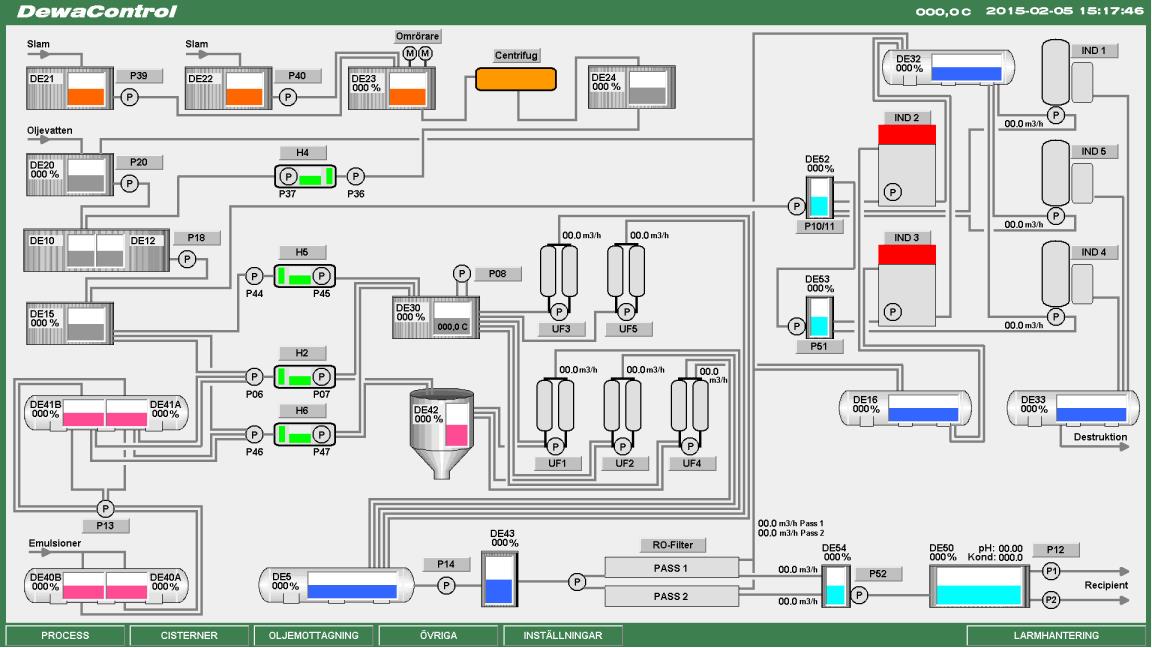

The flow between the differens stages of our process is fully automated and the different machines communicated with one another in order to purify each batch of water correctly. This automation means that the water can be sent back in the process one step if the water does not quite meet the requirements that the next machines needs in order to take over. The system also sends out different types of warnings to our staff in the case of something requiring manual attention.

Is is this automated system that allows us to keep our plant going every day, year round.

Map of the process: